-

ti abẹnu ga titẹ hydroforming gbóògì ila

Ṣiṣẹda titẹ giga ti inu, ti a tun pe ni hydroforming tabi hydraulic forming, jẹ ilana dida ohun elo ti o lo omi bi alabọde ati ṣaṣeyọri idi ti ṣiṣẹda awọn ẹya ṣofo nipa ṣiṣakoso titẹ inu ati ṣiṣan ohun elo. Hydro Forming jẹ iru ẹrọ imọ-ẹrọ hydraulic. O jẹ ilana kan ninu eyiti a ti lo tube bi billet, ati pe a tẹ billet tube sinu iho apẹrẹ lati ṣe agbekalẹ iṣẹ iṣẹ ti a beere nipa lilo omi titẹ giga-giga ati ifunni axial. Fun awọn ẹya ti o ni awọn aake ti o tẹ, billet tube nilo lati tẹ tẹlẹ sinu apẹrẹ ti apakan ati lẹhinna tẹ. Gẹgẹbi iru awọn ẹya ti o ṣẹda, titẹ titẹ giga ti inu ti pin si awọn ẹka mẹta:

(1) idinku tube hydroforming;

(2) tube inu atunse axis hydroforming;

(3) ọpọ-kọja tube ga-titẹ hydroforming. -

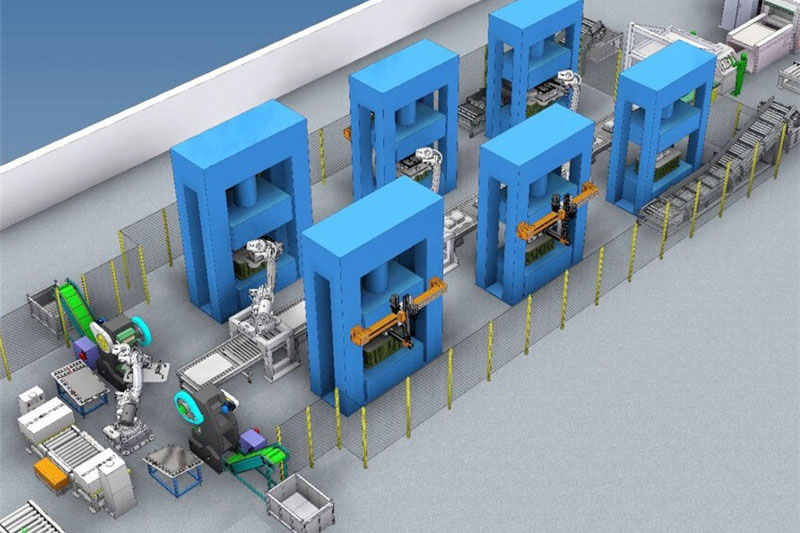

Ni kikun Aládàáṣiṣẹ Sheet irin Stamping Hydraulic Press Line Production Line fun adaṣe

Awọn kikun Automated Sheet Sheet Metal Stamping Hydraulic Press Production Line ṣe iyipada ifunni atọwọdọwọ ibile ati laini apejọ ẹrọ ṣiṣi silẹ nipasẹ iṣakojọpọ awọn apa roboti fun mimu ohun elo adaṣe adaṣe ati awọn iṣẹ wiwa. Laini iṣelọpọ ọpọlọ lemọlemọfún n jẹ ki iṣelọpọ oye ṣiṣẹ ni awọn ile-iṣelọpọ stamping pẹlu iṣẹ aiṣedeede patapata jakejado ilana iṣelọpọ.

Laini iṣelọpọ jẹ ojutu gige-eti ti a ṣe apẹrẹ lati ṣe ilana ilana iṣelọpọ ti awọn paati adaṣe. Nipa rirọpo iṣẹ afọwọṣe pẹlu awọn apa roboti, laini iṣelọpọ yii ṣaṣeyọri ifunni adaṣe ati ikojọpọ awọn ohun elo, lakoko ti o tun ṣafikun awọn agbara wiwa ilọsiwaju. O n ṣiṣẹ lori ipo iṣelọpọ ọpọlọ lilọsiwaju, yiyipada awọn ile-iṣelọpọ stamping sinu awọn ohun elo iṣelọpọ smati.

-

Die Tryout Hydraulic Press fun Ohun-elo Irinṣẹ Apakan adaṣe

Awọn To ti ni ilọsiwaju Die Tryout Hydraulic Press, ti o ni idagbasoke nipasẹ JIANGDONG MACHINERY jẹ ẹya igbegasoke ti iṣẹ-iṣiro-ẹyọkan ti irin stamping hydraulic press. Ti a ṣe ni pataki fun n ṣatunṣe aṣiṣe apakan adaṣe, o ṣe ẹya awọn agbara iṣatunṣe ikọlu deede. Pẹlu deede-tuntun-itanran ti o to 0.05mm fun ikọlu ati awọn ipo atunṣe pupọ pẹlu iṣatunṣe aaye mẹrin-ẹrọ, atunṣe hydraulic servo, ati gbigbe-kere si isalẹ, titẹ hydraulic yii n pese iṣedede iyasọtọ ati irọrun fun idanwo m ati afọwọsi.

Awọn To ti ni ilọsiwaju Die Tryout Hydraulic Press jẹ ojutu gige-eti ti a ṣe lati pade awọn ibeere alailẹgbẹ ti mimu mimu fun awọn ẹya ọkọ ayọkẹlẹ. Ti a ṣe lori ipilẹ ti iṣẹ-igbesẹ ẹyọkan ti irin stamping hydraulic tẹ, ẹrọ imotuntun yii ṣafihan awọn agbara iṣatunṣe ọpọlọ ilọsiwaju lati rii daju pe idanwo kongẹ ati afọwọsi ti awọn apẹrẹ adaṣe. Pẹlu awọn ipo atunṣe oriṣiriṣi mẹta ti o wa, awọn oniṣẹ ni irọrun lati yan ọna atunṣe to dara julọ fun awọn iwulo wọn pato.

-

Kú Spotting Hydraulic Press fun konge Mold Atunṣe

Die Spotting Hydraulic Press jẹ ẹrọ amọja ti a ṣe apẹrẹ fun mimu mimu deede ati atunṣe. O dara ni pataki fun iṣelọpọ ati atunṣe alabọde si awọn apẹrẹ stamping titobi nla, pese titete mimu daradara, n ṣatunṣe aṣiṣe deede, ati awọn agbara ṣiṣe deede. Tẹtẹ hydraulic yii wa ni awọn fọọmu igbekale meji: pẹlu tabi laisi ohun elo yiyi mimu, da lori ẹya mimu ati awọn ibeere ilana iranran. Pẹlu iṣedede iṣakoso ikọlu giga rẹ ati awọn agbara ikọlu adijositabulu, titẹ hydraulic nfunni ni awọn aṣayan atunṣe-itanran mẹta ti o yatọ: atunṣe aaye mẹrin-ẹrọ, atunṣe hydraulic servo, ati gbigbe-kere si isalẹ.

Die Spotting Hydraulic Press jẹ ojutu ilọsiwaju ti imọ-ẹrọ pataki ti a ṣe apẹrẹ fun sisẹ mimu ati atunṣe ni awọn ile-iṣẹ bii adaṣe, ọkọ ofurufu, ati iṣelọpọ. Iṣakoso ọpọlọ gangan ati irọrun jẹ ki o jẹ ohun elo ti ko ṣe pataki fun ṣiṣatunṣe mimu, titete, ati sisẹ deede.

-

Alabọde ati ki o nipọn awo stamping ati iyaworan eefun ti tẹ laini gbóògì

Laini iṣelọpọ Iṣelọpọ Alabọde-nipọn Awo to ti ni ilọsiwaju ni awọn titẹ hydraulic marun, awọn gbigbe rola, ati awọn gbigbe igbanu. Pẹlu eto iyipada mimu iyara rẹ, laini iṣelọpọ n jẹ ki o yara ati mimu mimu mimu daradara. O lagbara lati ṣaṣeyọri dida ipele 5 ati gbigbe awọn iṣẹ ṣiṣe, idinku kikankikan iṣẹ, ati irọrun iṣelọpọ daradara ti awọn ohun elo ile. Gbogbo laini iṣelọpọ ti wa ni adaṣe ni kikun nipasẹ isọpọ ti PLC ati iṣakoso aarin, ni idaniloju iṣelọpọ ti o dara julọ.

Laini Gbóògì jẹ ojutu-ti-ti-aworan ti a ṣe apẹrẹ fun iṣelọpọ daradara ti awọn ohun elo ti o jinlẹ lati awọn awo alabọde-alabọde. O daapọ agbara ati konge ti awọn ẹrọ hydraulic pẹlu irọrun ti awọn eto mimu ohun elo adaṣe, ti o mu ki iṣelọpọ imudara ati dinku awọn ibeere iṣẹ laala.

-

Nikan-igbese Sheet irin Stamping Hydraulic Press

Wa Nikan-igbese Sheet irin Stamping Hydraulic Press wa ni mejeji mẹrin-iwe ati fireemu ẹya. Ti a ni ipese pẹlu timutimu hydraulic didan sisale, tẹ yii ngbanilaaye ọpọlọpọ awọn ilana bii titan dì irin, gige (pẹlu ẹrọ ifibọ), atunse, ati finnifinni. Ẹrọ naa ṣe ẹya hydraulic olominira ati awọn ọna itanna, gbigba fun awọn atunṣe ati awọn ipo iṣẹ meji: ọmọ lilọsiwaju (ologbele-laifọwọyi) ati atunṣe afọwọṣe. Awọn ipo iṣiṣẹ titẹ pẹlu silinda timutimu hydraulic ko ṣiṣẹ, nina, ati isunmọ yiyipada, pẹlu yiyan aifọwọyi laarin titẹ igbagbogbo ati ọpọlọ fun ipo kọọkan. Ti a lo jakejado ni ile-iṣẹ adaṣe fun isamisi awọn ohun elo irin dì tinrin, o nlo awọn imu nina, awọn kuku punch, ati awọn apẹrẹ iho fun awọn ilana pẹlu nínàá, punching, atunse, gige, ati ipari ti o dara. Awọn ohun elo rẹ tun fa si aaye afẹfẹ, gbigbe ọkọ oju-irin, ẹrọ ogbin, awọn ohun elo ile, ati ọpọlọpọ awọn aaye miiran.

-

Ọkọ ayọkẹlẹ inu ilohunsoke hydraulic Press Ati Laini iṣelọpọ

Tẹtẹ Inu ilohunsoke Ọkọ ayọkẹlẹ ati Laini Gbóògì ti o dagbasoke nipasẹ JIANGDONG MACHINERY jẹ lilo akọkọ fun tutu ati ilana imudọgba gbona ti awọn paati inu inu ọkọ ayọkẹlẹ gẹgẹbi awọn dasibodu, awọn carpets, awọn orule, ati awọn ijoko. O le ni ipese pẹlu awọn eto alapapo gẹgẹbi epo gbona tabi nya si da lori awọn ibeere ilana, pẹlu ifunni laifọwọyi ati awọn ẹrọ ikojọpọ, awọn adiro alapapo ohun elo, ati ohun elo igbale lati ṣe laini iṣelọpọ adaṣe ni kikun.

-

Iyara Giga Aifọwọyi Fine-Blanking hydraulic Press Line fun Awọn ohun elo Irin

Aifọwọyi Ga-iyara Fine-Blanking hydraulic Press Line jẹ apẹrẹ fun ilana isọdi deede ti awọn ohun elo irin, ni pataki ounjẹ si iṣelọpọ ti awọn oriṣiriṣi awọn ẹya ijoko ọkọ ayọkẹlẹ adaṣe gẹgẹbi awọn agbeko, awọn abọ jia, awọn oluyipada igun, ati awọn paati biriki bii awọn ratchets, awọn pawls, awọn apẹrẹ ti n ṣatunṣe, fa awọn apa, titari awọn ọpa, awọn awo inu, ati awọn awo inu. Pẹlupẹlu, o tun munadoko fun iṣelọpọ awọn paati ti a lo ninu awọn igbanu ijoko, gẹgẹbi awọn ahọn idii, awọn oruka jia inu, ati awọn pawls. Laini iṣelọpọ yii ni awọn ẹrọ hydraulic kan ti o dara-pipe ti o ga julọ, ẹrọ ifunni aifọwọyi mẹta-ni-ọkan, ati eto ikojọpọ laifọwọyi. O nfunni ni ifunni aifọwọyi, ṣofo aifọwọyi, gbigbe apakan aifọwọyi, ati awọn iṣẹ gige egbin laifọwọyi. Laini iṣelọpọ le ṣe aṣeyọri oṣuwọn ọmọ ti 35-50spm.web, awo atilẹyin; Latch, oruka inu, ratchet, ati bẹbẹ lọ.

-

Ilẹkun mọto ayọkẹlẹ Hemming Hydraulic Press

Ilẹkun Ọkọ ayọkẹlẹ Hemming Hydraulic Press jẹ apẹrẹ pataki fun ilana hemming ati awọn iṣẹ ofo ati gige ti awọn ilẹkun ọkọ ayọkẹlẹ osi ati ọtun, awọn ideri ẹhin mọto, ati awọn ideri engine. O ti ni ipese pẹlu eto iyipada ku ni iyara, awọn iṣẹ iṣẹ gbigbe lọpọlọpọ ni awọn ọna pupọ, ẹrọ mimu ku laifọwọyi, ati eto idanimọ iku kan.

-

irin alagbara, irin omi ifọwọ gbóògì ila

Laini iṣelọpọ omi ti irin alagbara, irin jẹ laini iṣelọpọ adaṣe adaṣe ti o pẹlu awọn ilana bii yiyi okun irin, gige, ati stamping lati ṣe apẹrẹ awọn ifọwọ. Laini iṣelọpọ yii nlo awọn roboti lati rọpo iṣẹ afọwọṣe, gbigba fun ipari adaṣe ti iṣelọpọ ifọwọ.

Laini iṣelọpọ omi ti irin alagbara, irin ni awọn ẹya akọkọ meji: apakan ipese ohun elo ati ẹyọ stamping rii. Awọn ẹya meji wọnyi ni asopọ nipasẹ ẹyọ gbigbe eekaderi, eyiti o ṣe irọrun gbigbe awọn ohun elo laarin wọn. Ẹka ipese ohun elo pẹlu ohun elo gẹgẹbi awọn unwinders coil, awọn laminators fiimu, awọn alapin, awọn gige, ati awọn akopọ. Ẹka gbigbe eekaderi ni awọn ọkọ gbigbe, awọn laini akopọ ohun elo, ati awọn laini ibi ipamọ pallet ofo. Ẹka stamping ni awọn ilana mẹrin: gige igun, nina akọkọ, nina keji, gige eti, eyiti o kan lilo awọn titẹ hydraulic ati adaṣe robot.

Agbara iṣelọpọ ti laini yii jẹ awọn ege meji fun iṣẹju kan, pẹlu iṣelọpọ lododun ti isunmọ awọn ege 230,000.

-

Laini Gbóògì Stamping gbigbona ti o ga julọ fun Irin Agbara giga ultral (Aluminiomu)

Laini Gbóògì Stamping gbigbona ti o ga julọ fun irin-giga giga-giga giga (Aluminiomu) jẹ ojutu iṣelọpọ-ti-ti-aworan fun iṣelọpọ awọn ẹya ara ẹrọ adaṣe ti o ni iwọn eka nipa lilo ilana imudani gbona. Pẹlu awọn ẹya bii ifunni ohun elo iyara, titẹ hydraulic ti o gbona ni iyara, awọn mimu omi tutu, eto imupadabọ ohun elo adaṣe, ati awọn aṣayan ṣiṣe atẹle bi fifun ibọn, gige laser, tabi gige gige laifọwọyi ati eto ṣofo, laini iṣelọpọ yii nfunni ni iṣẹ ṣiṣe ati ṣiṣe to ṣe pataki.

-

Ultra High Agbara Irin (Aluminiomu) Aifọwọyi Ige Tutu / Blanking Production Line

Awọn irin-giga ti o ga julọ (Aluminiomu) Aifọwọyi Imudaniloju Imudaniloju Imudaniloju Aifọwọyi jẹ ọna ẹrọ ti o wa ni ipo-ọna ti a ṣe apẹrẹ fun ifiweranṣẹ-ifiweranṣẹ ti irin-giga tabi aluminiomu lẹhin ti o gbona stamping. O Sin bi ohun daradara rirọpo fun ibile lesa Ige ẹrọ. Laini iṣelọpọ yii ni awọn titẹ hydraulic meji pẹlu awọn ẹrọ gige, awọn apa roboti mẹta, ikojọpọ laifọwọyi ati eto gbigbe, ati eto gbigbe ti o gbẹkẹle. Pẹlu awọn agbara adaṣe rẹ, laini iṣelọpọ yii ṣe iranlọwọ lemọlemọfún ati awọn ilana iṣelọpọ iwọn didun giga.

Awọn irin-giga ti o ga julọ (Aluminiomu) Aifọwọyi Aifọwọyi Imujade Imujade Imudaniloju ti wa ni pataki fun ṣiṣe-ifiweranṣẹ ti irin-giga tabi awọn ohun elo aluminiomu ti o tẹle awọn ilana imudani ti o gbona. O pese ojutu ti o ni igbẹkẹle lati rọpo cumbersome ati awọn ọna gige ina lesa ibile ti n gba akoko. Laini iṣelọpọ yii daapọ imọ-ẹrọ to ti ni ilọsiwaju, awọn irinṣẹ konge, ati adaṣe lati ṣaṣeyọri lainidi ati iṣelọpọ daradara.