-

irin alagbara, irin omi ifọwọ gbóògì ila

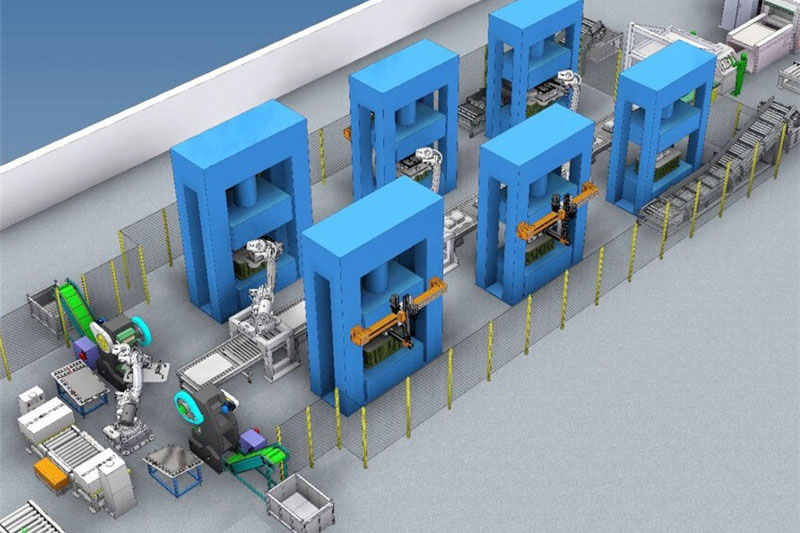

Laini iṣelọpọ omi ti irin alagbara, irin jẹ laini iṣelọpọ adaṣe adaṣe ti o pẹlu awọn ilana bii yiyi okun irin, gige, ati stamping lati ṣe apẹrẹ awọn ifọwọ. Laini iṣelọpọ yii nlo awọn roboti lati rọpo iṣẹ afọwọṣe, gbigba fun ipari adaṣe ti iṣelọpọ ifọwọ.

Laini iṣelọpọ omi ti irin alagbara, irin ni awọn ẹya akọkọ meji: apakan ipese ohun elo ati ẹyọ stamping rii. Awọn ẹya meji wọnyi ni asopọ nipasẹ ẹyọ gbigbe eekaderi, eyiti o ṣe irọrun gbigbe awọn ohun elo laarin wọn. Ẹka ipese ohun elo pẹlu ohun elo gẹgẹbi awọn unwinders coil, awọn laminators fiimu, awọn alapin, awọn gige, ati awọn akopọ. Ẹka gbigbe eekaderi ni awọn ọkọ gbigbe, awọn laini akopọ ohun elo, ati awọn laini ibi ipamọ pallet ofo. Ẹka stamping ni awọn ilana mẹrin: gige igun, nina akọkọ, nina keji, gige eti, eyiti o kan lilo awọn titẹ hydraulic ati adaṣe robot.

Agbara iṣelọpọ ti laini yii jẹ awọn ege meji fun iṣẹju kan, pẹlu iṣelọpọ lododun ti isunmọ awọn ege 230,000.

-

SMC/BMC/GMT/PCM Composite Molding Hydraulic Press

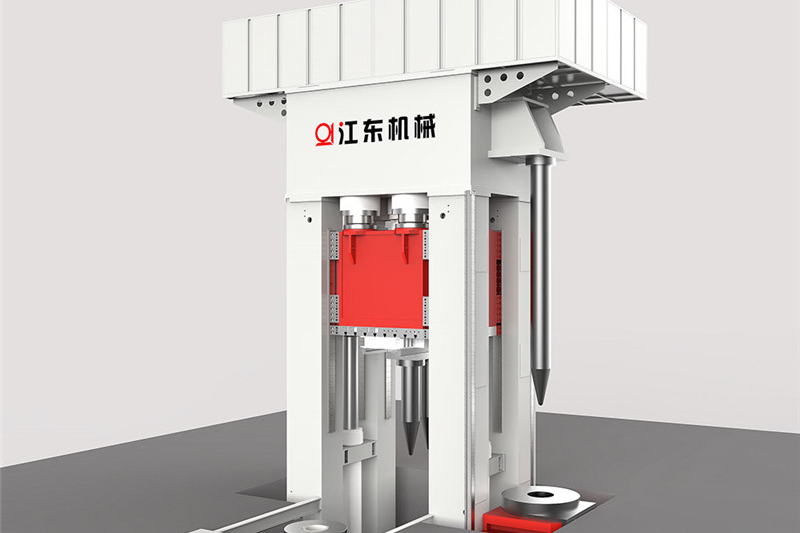

Lati rii daju iṣakoso kongẹ lakoko ilana mimu, ẹrọ hydraulic ti wa ni ipese pẹlu eto iṣakoso hydraulic servo to ti ni ilọsiwaju. Eto yii ṣe imudara iṣakoso ipo, iṣakoso iyara, iṣakoso iyara ṣiṣi micro, ati deede paramita titẹ. Awọn išedede iṣakoso titẹ le de ọdọ ± 0.1MPa. Awọn paramita bii ipo ifaworanhan, iyara isalẹ, iyara titẹ-tẹlẹ, iyara ṣiṣi micro, iyara ipadabọ, ati igbohunsafẹfẹ eefi le ṣeto ati ṣatunṣe laarin iwọn kan lori iboju ifọwọkan. Eto iṣakoso jẹ fifipamọ agbara, pẹlu ariwo kekere ati ipa hydraulic pọọku, pese iduroṣinṣin to gaju.

Lati koju awọn ọran imọ-ẹrọ gẹgẹbi awọn ẹru ti ko ni iwọntunwọnsi ti o fa nipasẹ awọn ẹya inọ asymmetric ati awọn iyapa sisanra ni awọn ọja tinrin alapin nla, tabi lati pade awọn ibeere ilana gẹgẹbi ibora inu-mi ati didimu ti o jọra, tẹ hydraulic le ni ipese pẹlu ohun elo ipele ipele igun mẹrẹrin lẹsẹkẹsẹ. Ẹrọ yii nlo awọn sensọ iṣipopada to gaju ati awọn falifu servo idahun igbohunsafẹfẹ giga-giga lati ṣakoso iṣẹ atunṣe amuṣiṣẹpọ ti awọn oṣere silinda mẹrin. O ṣe aṣeyọri deede ipele igun mẹrin ti o pọju ti o to 0.05mm lori gbogbo tabili.

-

LFT-D okun gigun fikun thermoplastic funmorawon taara laini iṣelọpọ

LFT-D okun gigun fikun thermoplastic funmorawon taara laini iṣelọpọ iṣipopada jẹ ojutu okeerẹ fun ṣiṣẹda awọn ohun elo idapọpọ didara to ga julọ daradara. Laini iṣelọpọ yii ni eto itọnisọna okun okun gilasi kan, ilọpo meji-daba gilasi fiber ṣiṣu dapọ extruder, gbigbe ohun elo alapapo, eto mimu ohun elo roboti, titẹ eefun ti iyara, ati apakan iṣakoso aarin.

Ilana iṣelọpọ bẹrẹ pẹlu ifunni okun gilasi ti o tẹsiwaju sinu extruder, nibiti o ti ge ati ki o jade sinu fọọmu pellet. Awọn pellets ti wa ni kikan ati ki o yarayara sinu apẹrẹ ti o fẹ nipa lilo ẹrọ mimu ohun elo roboti ati titẹ hydraulic ti o yara. Pẹlu agbara iṣelọpọ lododun ti 300,000 si awọn ikọlu 400,000, laini iṣelọpọ yii ṣe idaniloju iṣelọpọ giga.

-

Erogba Fiber High Titẹ Resini Gbigbe Molding (HP-RTM) ohun elo

Ohun elo Carbon Fiber High Pressure Resin Molding (HP-RTM) ohun elo jẹ ojutu gige-eti ti o dagbasoke ni ile fun iṣelọpọ awọn paati okun erogba to gaju. Laini iṣelọpọ okeerẹ yii ni awọn eto iṣapejọ aṣayan, titẹ amọja HP-RTM, eto abẹrẹ resini titẹ giga HP-RTM kan, awọn roboti, ile-iṣẹ iṣakoso laini iṣelọpọ, ati ile-iṣẹ ẹrọ yiyan. Eto abẹrẹ resini titẹ giga ti HP-RTM ni eto wiwọn, eto igbale, eto iṣakoso iwọn otutu, ati gbigbe ohun elo aise ati eto ipamọ. O nlo titẹ-giga, ọna abẹrẹ ifaseyin pẹlu awọn ohun elo paati mẹta. Tẹtẹ amọja ti ni ipese pẹlu eto ipele igun mẹrin, ti o funni ni deede ipele ipele iwunilori ti 0.05mm. O tun ṣe ẹya awọn agbara ṣiṣi bulọọgi, gbigba fun awọn akoko iṣelọpọ iyara ti awọn iṣẹju 3-5. Ohun elo yii ngbanilaaye iṣelọpọ ipele ati iṣelọpọ irọrun ti adani ti awọn paati okun erogba.

-

Irin extrusion / gbona kú forging eefun ti tẹ

Awọn irin extrusion / gbona kú forging hydraulic press jẹ ẹya to ti ni ilọsiwaju ẹrọ ẹrọ fun ga-didara, daradara, ati kekere-agbara processing ti irin irinše pẹlu pọọku tabi ko si gige awọn eerun. O ti ni ohun elo jakejado ni ọpọlọpọ awọn ile-iṣẹ iṣelọpọ bii adaṣe, ẹrọ, ile-iṣẹ ina, afẹfẹ, aabo, ati ohun elo itanna.

Irin extrusion / gbona kú forging eefun ti tẹ ti wa ni pataki apẹrẹ fun awọn tutu extrusion, gbona extrusion, gbona forging, ati ki o gbona kú forging lara lakọkọ, bi daradara bi konge finishing ti irin irinše.

-

titanium alloy superplastic lara eefun ti tẹ

Superplastic Forming Hydraulic press jẹ ẹrọ amọja ti a ṣe apẹrẹ fun isunmọ nẹtiwọọki ti o ṣẹda awọn paati eka ti a ṣe lati awọn ohun elo ti o ṣoro-si-fọọmu pẹlu awọn sakani iwọn otutu abuku dín ati resistance abuku giga. O wa ohun elo ibigbogbo ni awọn ile-iṣẹ bii afẹfẹ, ọkọ ofurufu, ologun, aabo, ati iṣinipopada iyara-giga.

Ẹrọ hydraulic yii nlo awọn ohun elo ti o ga julọ, gẹgẹbi awọn ohun elo titanium, awọn ohun elo aluminiomu, awọn ohun elo iṣuu magnẹsia, ati awọn ohun elo ti o ga julọ, nipa ṣiṣe atunṣe iwọn ọkà ti ohun elo aise si ipo ti o ga julọ. Nipa lilo titẹ kekere-kekere ati awọn iyara iṣakoso, tẹ ṣaṣeyọri abuku superplastic ti ohun elo naa. Yi rogbodiyan ẹrọ ilana kí isejade ti irinše lilo significantly kere èyà akawe si mora lara imuposi.

-

Free forging eefun ti tẹ

Awọn Free Forging Hydraulic Press jẹ ẹrọ amọja ti a ṣe apẹrẹ fun awọn iṣẹ ayederu ọfẹ ọfẹ. O ṣe iranlọwọ fun ipari ti awọn ilana isọdi oriṣiriṣi bii elongation, ibinu, punching, fifẹ, yiya igi, yiyi, atunse, yiyi, ati gige fun iṣelọpọ awọn ọpa, awọn ọpa, awọn awo, awọn disiki, awọn oruka, ati awọn paati ti o ni ipin ati awọn apẹrẹ onigun mẹrin. Ni ipese pẹlu awọn ohun elo oluranlọwọ ibaramu gẹgẹbi ẹrọ ayederu, awọn ọna ṣiṣe mimu ohun elo, awọn tabili ohun elo rotari, awọn anvils, ati awọn ọna gbigbe, tẹ n ṣepọ laisiyonu pẹlu awọn paati wọnyi lati pari ilana ayederu. O wa awọn ohun elo jakejado ni awọn ile-iṣẹ bii afẹfẹ ati oju-ofurufu, ikole ọkọ oju-omi, iran agbara, agbara iparun, irin-irin, ati awọn kemikali petrochemicals.

-

Light Alloy Liquid Die Forging / semisolid lara Production Line

Imọlẹ Alloy Liquid Die Forging Production Line jẹ imọ-ẹrọ ti o-ti-ti-aworan ti o ṣajọpọ awọn anfani ti simẹnti ati awọn ilana ṣiṣe lati ṣaṣeyọri awọn apẹrẹ ti o sunmọ-net. Laini iṣelọpọ tuntun yii nfunni ni ọpọlọpọ awọn anfani, pẹlu ṣiṣan ilana kukuru, ọrẹ ayika, agbara kekere, eto apakan aṣọ, ati iṣẹ ṣiṣe ẹrọ giga. O ni omi CNC multifunctional ku forging hydraulic tẹ, eto fifa omi pipo aluminiomu, roboti kan, ati eto iṣọpọ ọkọ akero kan. Laini iṣelọpọ jẹ ijuwe nipasẹ iṣakoso CNC rẹ, awọn ẹya oye, ati irọrun.

-

Inaro Gas Silinda/Bullet Housing Drawing Line Production

Silinda Gaasi Inaro / Bullet Housing Drawing Line jẹ apẹrẹ pataki fun iṣelọpọ awọn ẹya ife-apẹrẹ (apẹrẹ agba) pẹlu opin isalẹ ti o nipọn, gẹgẹbi awọn apoti oriṣiriṣi, awọn silinda gaasi, ati awọn ile ọta ibọn. Laini iṣelọpọ yii ngbanilaaye awọn ilana pataki mẹta: ibinu, punching, ati iyaworan. O pẹlu ohun elo bii ẹrọ ifunni, ileru alapapo alabọde-igbohunsafẹfẹ, igbanu conveyor, ifunni robot / ọwọ ẹrọ, ibinu ati punching hydraulic press, tabili ifaworanhan meji-meji, gbigbe robot / ọwọ ẹrọ, iyaworan hydraulic tẹ, ati eto gbigbe ohun elo.

-

Gaasi Silinda Petele yiya Laini

Laini iṣelọpọ iyaworan petele gaasi jẹ apẹrẹ fun ilana sisọ nina ti awọn silinda gaasi gigun-gun. O gba ilana sisọ nina petele kan, ti o ni ẹyọ ori laini, robot ohun elo ikojọpọ, titẹ petele gigun-ọpọlọ, ẹrọ ipadasẹhin ohun elo, ati ẹyọ iru laini. Laini iṣelọpọ yii nfunni ni ọpọlọpọ awọn anfani bii iṣiṣẹ irọrun, iyara dida giga, igun gigun gigun, ati ipele adaṣe giga kan.

-

Gantry Straightening Hydraulic Press fun awọn awo

Wa gantry straightening hydraulic press jẹ apẹrẹ pataki fun titọ ati awọn ilana ṣiṣe ti awọn awo irin ni awọn ile-iṣẹ bii afẹfẹ, ọkọ oju omi, ati irin-irin. Ohun elo naa ni ori silinda gbigbe, fireemu gantry alagbeka kan, ati tabili iṣẹ ti o wa titi. Pẹlu agbara lati ṣe iṣipopada petele lori mejeeji ori silinda ati fireemu gantry ni gigun ti tabili iṣẹ, gantry wa titọ hydraulic tẹ ṣe idaniloju deede ati atunṣe awo ni kikun laisi awọn aaye afọju eyikeyi. Silinda akọkọ ti tẹ ti ni ipese pẹlu iṣẹ-iṣipopada sisale, gbigba fun titọ awo deede. Ni afikun, a ṣe apẹrẹ tabili iṣẹ pẹlu ọpọlọpọ awọn silinda gbigbe ni agbegbe awo ti o munadoko, eyiti o jẹ ki fifi sii awọn bulọọki atunṣe ni awọn aaye kan pato ati tun ṣe iranlọwọ ni gbigbe awọn plates.ifting ti awo naa.

-

Aifọwọyi Gantry Straightening Hydraulic Press fun Pẹpẹ Iṣura

Gantry laifọwọyi wa ti n ṣatunṣe hydraulic tẹ jẹ laini iṣelọpọ pipe ti a ṣe apẹrẹ lati taara daradara ati atunṣe ọja ọpa irin. O ni ẹyọ titọna eefun ti alagbeka kan, eto iṣakoso wiwa (pẹlu wiwa taara iṣẹ-ṣiṣe, wiwa igun yiyi iṣẹ, wiwa aaye titọ, ati wiwa nipo nipo), eto iṣakoso eefun, ati eto iṣakoso itanna kan. Yi wapọ eefun ti tẹ ni o lagbara ti automating awọn straightening ilana fun irin igi iṣura, aridaju superior išedede ati ṣiṣe.